Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

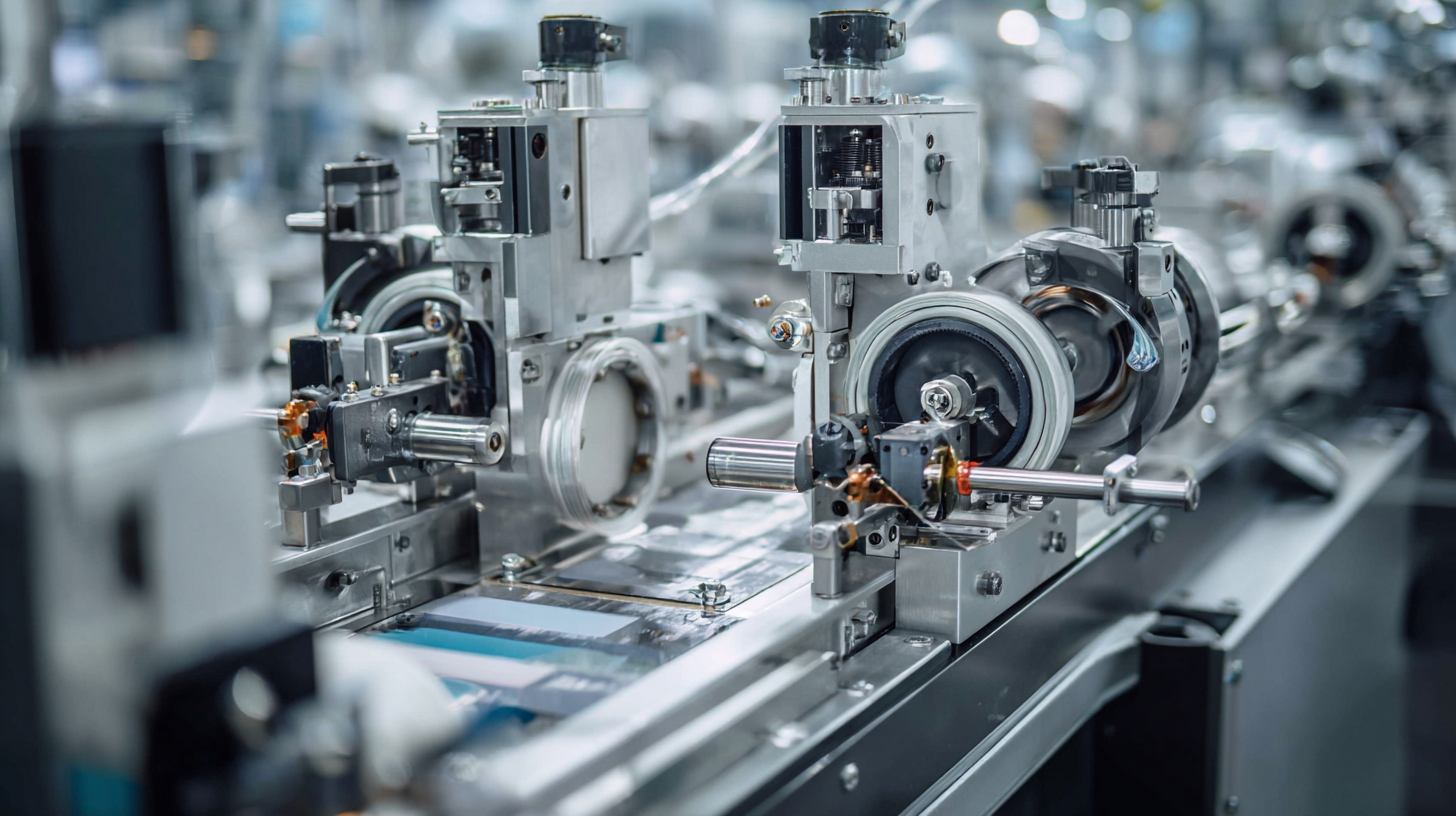

In the ever-evolving landscape of manufacturing, the pursuit of efficiency has become paramount. As companies seek to optimize their operations, manual machines have emerged as a key player in boosting productivity levels remarkably. The integration of manual machines into manufacturing processes offers a unique blend of precision and flexibility, enabling workers to perform tasks with greater accuracy than ever before. Recent studies reveal that these machines can enhance efficiency by up to 30%, significantly impacting overall production rates and quality.

In the ever-evolving landscape of manufacturing, the pursuit of efficiency has become paramount. As companies seek to optimize their operations, manual machines have emerged as a key player in boosting productivity levels remarkably. The integration of manual machines into manufacturing processes offers a unique blend of precision and flexibility, enabling workers to perform tasks with greater accuracy than ever before. Recent studies reveal that these machines can enhance efficiency by up to 30%, significantly impacting overall production rates and quality.

By harnessing the capabilities of manual machines, manufacturers are not only improving their output but also fostering a workforce skilled in hands-on techniques. This exploration into the role of manual machines unveils their potential to unlock unprecedented levels of efficiency and productivity in the manufacturing sector, paving the way for a more sustainable and agile industrial future.

Understanding Manual Machines in Manufacturing Efficiency

Understanding the role of manual machines in manufacturing efficiency is essential as industries strive to enhance productivity. Manual machines, when utilized effectively, can lead to significant efficiency gains—up to 30%—by improving precision and ensuring more accurate outputs. This hands-on approach allows workers to closely monitor the production process, identify potential issues early, and adjust operations in real-time, resulting in fewer defects and reduced waste.

As manufacturers increasingly integrate digital technologies and artificial intelligence into their operations, the synergy between manual machines and advanced technologies becomes evident. AI can enhance the functionality of manual assembly lines by providing data insights that inform decision-making, ultimately leading to improved productivity and quality. By emphasizing targeted investments in their digital infrastructure, manufacturers can address the ongoing skills gap and prepare their workforce to operate more effectively alongside both manual and automated machines. This integration not only boosts efficiency but also fosters an adaptive manufacturing environment capable of keeping pace with evolving market demands.

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

| Machine Type | Efficiency Gain (%) | Production Time Reduction (%) | Cost Saving (%) | Error Rate Reduction (%) |

|---|---|---|---|---|

| Lathe Machines | 30 | 20 | 15 | 25 |

| Milling Machines | 28 | 25 | 12 | 30 |

| Drilling Machines | 32 | 18 | 8 | 22 |

| Grinding Machines | 29 | 22 | 10 | 27 |

| CNC Machines | 35 | 30 | 15 | 40 |

The Role of Precision in Boosting Productivity

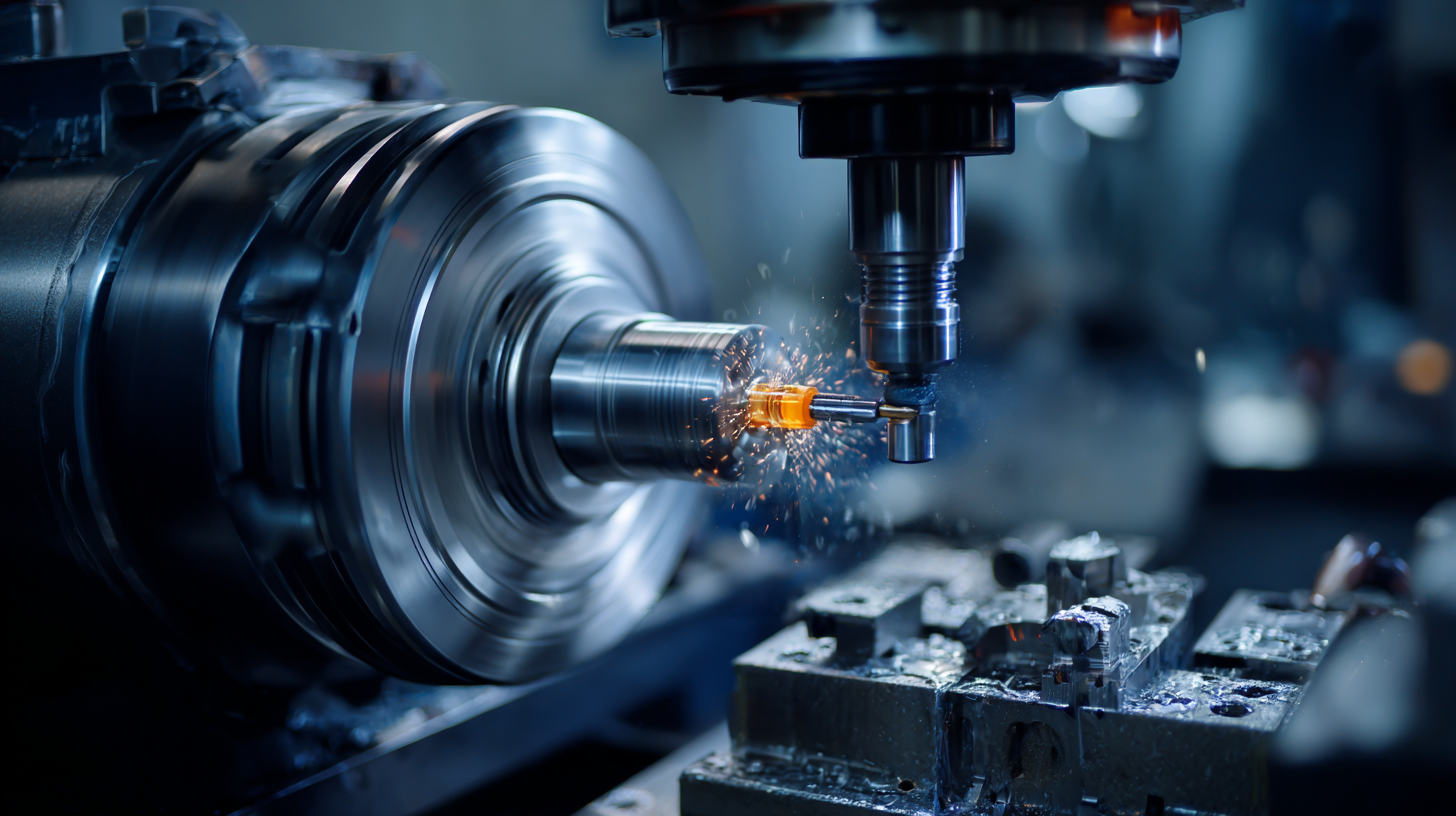

In the realm of manufacturing, precision is paramount. The use of manual machines not only brings about significant efficiency gains but also enhances the overall quality of production. A recent report by the National Institute of Standards and Technology indicates that improving precision in machining can lead to up to 30% lower rejection rates, translating to higher output and reduced material waste. This not only increases productivity but also boosts profitability for manufacturers striving to stay competitive in the industry.

To leverage precision effectively, manufacturers should consider investing in employee training focused on manual machining techniques. Skilled operators are more likely to achieve the exact tolerances required, leading to better product consistency. Furthermore, integrating routine maintenance checks on manual machines can help identify potential issues before they escalate, ensuring consistent performance and minimizing downtime.

**Tips:**

1. Encourage a culture of precision among your workforce by emphasizing the importance of accuracy in every step of the manufacturing process.

2. Invest in precision measurement tools to facilitate continuous monitoring and adjustments, ensuring that machine settings reflect the required specifications accurately.

3. Analyze and document the impact of precision improvements on productivity, setting benchmarks that can drive future enhancements in manufacturing practices.

Evaluating the 30% Efficiency Gains from Manual Machines

In the evolving landscape of manufacturing, manual machines have made a notable comeback, leading to substantial efficiency gains. According to a report by the National Association of Manufacturers (NAM), integrating manual operations in manufacturing can yield an efficiency increase of up to 30%. This uptick can largely be attributed to the enhanced flexibility and precision that manual machines offer. By allowing skilled workers to make real-time adjustments, businesses can significantly reduce waste and improve quality, positioning themselves ahead of the competition.

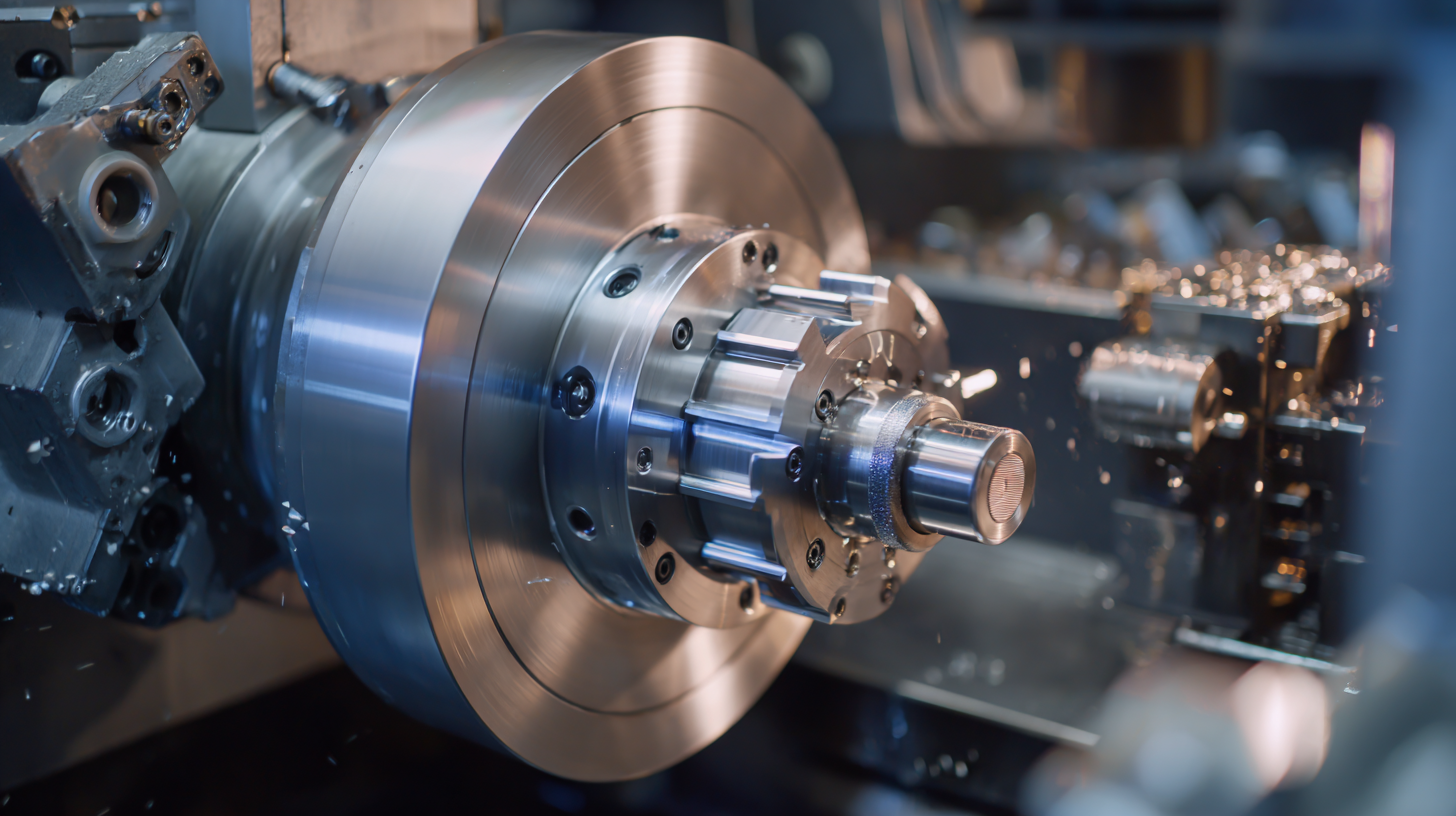

Implementing manual machines doesn't just mean higher productivity; it also encourages a culture of craftsmanship. As workers engage more deeply with their tools, they develop skills that lead to innovation in processes and products. A study by McKinsey & Company found that organizations fostering skilled labor alongside manual machinery can achieve greater operational effectiveness than those relying solely on automation.

Best Practices for Implementing Manual Machines in Production

Implementing manual machines in manufacturing processes can lead to significant efficiency gains, with studies indicating improvements of up to 30% in productivity. To capitalize on these benefits, organizations should adopt best practices that enhance the integration of manual machines into their workflows. According to a report by the Manufacturing Institute, up to 70% of manufacturers who have transitioned to manual machinery have reported increased employee engagement and skill development, as operators become more involved in the machine’s performance and maintenance.

One of the best practices includes providing comprehensive training programs for operators, ensuring they are well-versed in both the technical and operational aspects of the machines. A survey by IndustryWeek revealed that companies investing in employee training saw a 23% reduction in downtime caused by operator errors. Additionally, regular maintenance schedules should be established to keep the machines in optimal working condition, as failure to do so can lead to costly inefficiencies. According to a report from McKinsey, maintaining machinery effectively can reduce maintenance costs by 25%, allowing manufacturers to focus resources on further productivity enhancements.

Unlocking Precision: Efficiency Gains with Manual Machines in Manufacturing

Case Studies: Success Stories of Increased Productivity

In recent years, many manufacturing companies have turned to manual machines as a means of enhancing productivity. Case studies reveal that organizations implementing these machines have experienced remarkable efficiency gains. For instance, a small automotive parts manufacturer integrated manual lathes and milling machines into their production line, resulting in a 30% increase in output. By allowing skilled operators to have greater control over the machining process, the company reduced waste and improved the quality of its products.

Another success story comes from a precision engineering firm that embraced manual machining to fine-tune its production methods. By training employees to operate manual machines effectively, the company reduced machine setup time and minimized downtime. This strategic move not only enhanced productivity but also fostered a culture of craftsmanship among the workers, leading to a more engaged and motivated workforce. These case studies illustrate how manual machines can serve as a pivotal solution for manufacturers aiming to boost productivity while maintaining high standards of quality.

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.