The Future of Machine Tools Innovations Transforming Manufacturing Processes

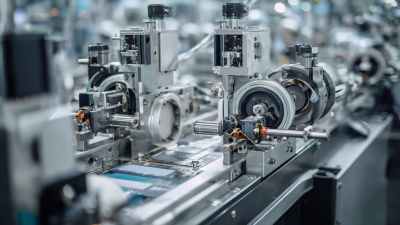

In the rapidly evolving landscape of manufacturing, innovations in machine tools are redefining the efficiencies and capabilities of production processes. As industries strive for greater precision and productivity, the integration of advanced technologies is becoming paramount. This article delves into the transformative innovations in machine tools, highlighting the pivotal role they play in enhancing manufacturing workflows. From automation and smart technologies to cutting-edge materials, the future of machine tools is not only about mechanical advancements but also about intelligent systems that adapt and optimize operations. Embracing digitalization and data analytics, manufacturers are poised to harness the full potential of machine tools, turning challenges into opportunities for growth and sustainability. As we explore these developments, we will provide insightful tips for industry professionals looking to leverage these innovations, ensuring they remain competitive in this dynamic sector.

How to Integrate AI and Machine Learning in Machine Tool Design

As the manufacturing landscape evolves, the integration of AI and machine learning in machine tool design is revolutionizing processes. According to a recent report from Deloitte, manufacturers that leverage AI can expect to see productivity boosts of up to 40%. By analyzing large datasets, AI algorithms can optimize cutting parameters, predict machine failures, and enhance the overall efficiency of manufacturing operations. This not only reduces downtime but also increases output quality, paving the way for more sophisticated production techniques and customizable manufacturing solutions.

Tips for integrating AI into machine tool design include starting with a thorough assessment of existing tools to identify suitable upgrade opportunities. Collaborating with technology partners who specialize in AI can accelerate the development process. Additionally, investing in employee training ensures that your workforce is equipped to work alongside intelligent systems, ultimately fostering a more innovative workplace culture.

Another crucial aspect is the incorporation of real-time data analytics. By integrating sensors and IoT technology, manufacturers can gather actionable insights, helping to continuously fine-tune processes. A report by McKinsey highlights that organizations implementing IoT solutions can improve their operational efficiency by up to 30%. This blend of AI, machine learning, and IoT is essential for future-proofing manufacturing operations.

How to Optimize Manufacturing Efficiency with Advanced CNC Technologies

The emergence of advanced CNC technologies is revolutionizing manufacturing efficiency across various industries. As companies increasingly adopt digital manufacturing solutions, the demand for high-precision and efficient machinery has never been greater. The CNC machining center market alone is projected to experience significant growth, expected to reach approximately $143.48 billion in 2025, with further expansion towards an estimated $216.94 billion by 2033. This surge is driven by the need for environmentally friendly, cost-effective solutions that enable manufacturers to transition from traditional operations to automated processes.

By leveraging advanced CNC systems, manufacturers can optimize their production workflows, drastically improving both quality and productivity. These cutting-edge technologies facilitate precise machining and higher output rates, thereby meeting the rising expectations of various industries. As companies invest in these innovations, they not only enhance their competitive edge but also contribute to sustainable manufacturing practices, thereby addressing both operational efficiency and environmental concerns simultaneously. The integration of state-of-the-art CNC technologies signals a transformative shift towards smarter, more agile manufacturing landscapes.

How to Implement Automation in Machine Tool Operations

The future of machine tools is undeniably intertwined with the implementation of automation, transforming manufacturing processes across various sectors. As highlighted in recent market reports, the global CNC machine market is projected to soar from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, with a compound annual growth rate (CAGR) of 9.9%. This significant growth emphasizes the industry's shift toward automated solutions that enhance efficiency and precision in machining operations.

To effectively implement automation in machine tool operations, companies should consider investing in robust AI-driven technologies that integrate seamlessly with existing workflows. As AI continues to reshape supply chains, it is important to note that organizations leveraging AI in their automation processes are witnessing reduced cycle times and improved decision-making capabilities. For instance, the Laser-Assisted Smart Lathes market is forecasted to reach USD 2,276.3 million by 2035, demonstrating a CAGR of 9.5% as more manufacturers embrace smart technologies.

**Tips for Implementation:**

1. **Assess Current Processes:** Evaluate existing workflows and identify areas where automation can deliver the most impact.

2. **Invest in Training:** Equip your workforce with the necessary skills to navigate new automated systems effectively.

3. **Pilot Programs:** Initiate pilot projects to test automation solutions in a controlled environment before scaling up.

These strategies will help manufacturers integrate automation not just as an enhancement, but as a foundational element driving future growth and innovation.

The Future of Machine Tools Innovations Transforming Manufacturing Processes

How to Leverage Additive Manufacturing for Innovative Tooling Solutions

The rise of additive manufacturing is revolutionizing tooling solutions in the manufacturing sector. According to a report by Grand View Research, the global additive manufacturing market is expected to reach $39.2 billion by 2025, growing at a CAGR of 23%. This rapid growth is driven by the technology's ability to create complex geometries and reduce material waste, which are critical factors for modern manufacturing processes. By leveraging these innovative capabilities, manufacturers can produce tooling that is not only more efficient but also more customized to specific operational requirements.

Additive manufacturing allows for the production of lighter, stronger, and more intricate tooling components that traditional methods struggle to achieve. For example, a case study by Stratasys highlighted how a leading automotive manufacturer reduced their tooling costs by 60% and lead times by 70% through 3D printing. This shift not only enhances production efficiency but also facilitates rapid prototyping during the design phase, enabling manufacturers to innovate faster and respond to market demands more effectively. As industries continue to embrace these advances, the potential for additive manufacturing to transform tooling solutions in manufacturing processes is both profound and promising.

How to Assess and Adopt Sustainable Practices in Machine Tool Production

Assessing and adopting sustainable practices in machine tool production is essential for contemporary manufacturers aiming to enhance efficiency and reduce environmental impact. To begin with, companies should evaluate their existing processes to identify areas where energy and resource consumption can be minimized. This evaluation can include auditing machinery for energy use, analyzing waste production, and inspecting supply chain practices. By employing life cycle assessments, businesses can quantify the environmental impact of their tools from production to disposal, allowing for informed decisions on upgrades and replacements.

Furthermore, integrating innovative technologies such as automation and smart manufacturing can substantially contribute to sustainability goals. Machine tools enhanced with IoT capabilities enable real-time monitoring of resource use, helping to optimize operations and reduce waste. Companies should also consider adopting alternative materials and eco-friendly lubricants that are less harmful to the environment. Collaborating with suppliers who prioritize sustainability can enhance the overall ecological footprint of production. Emphasizing continuous improvement and employee training on sustainable practices will foster a culture of responsible manufacturing, ensuring that sustainability becomes an integral part of the machine tool production process.

The Future of Machine Tools Innovations Transforming Manufacturing Processes

| Innovation | Description | Benefits | Sustainability Impact |

|---|---|---|---|

| Smart Manufacturing | Integration of IoT and AI in production machinery. | Increased efficiency and reduced downtime. | Optimized resource usage, reduced waste. |

| Additive Manufacturing | 3D printing technologies used for creating complex parts. | Customization and reduction in material costs. | Less material waste and energy consumption. |

| Automated Workflows | Fully automated processes with minimal human intervention. | Increased productivity and safety in the workplace. | Consistent quality and reduced energy use. |

| Energy-Efficient Machinery | Machines designed to consume less energy during operation. | Lower operational costs and extended machine life. | Significant reduction in carbon footprint. |

| Virtual Reality for Training | Using VR simulations for training operators. | Enhanced training effectiveness and reduced risk. | Less physical wear on machines used in training. |

Related Posts

-

The Future of Precision Machining Innovations Transforming Industry Standards

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.