The Future of Machine Manufacturing Innovations Transforming Industries

In today's rapidly evolving industrial landscape, the field of machine manufacturing stands at the forefront of innovation, reshaping the paradigms of production and efficiency across various sectors. As technological advancements pave the way for smarter, more automated processes, industries are embracing these changes to enhance their operational capabilities. This article explores the pivotal role of machine manufacturing innovations, delving into key methodologies and technologies that are transforming traditional manufacturing practices.

From the implementation of advanced robotics and artificial intelligence to the integration of sustainable materials, the future of machine manufacturing is not just about increasing output but also about fostering a more adaptable and resilient economy. By examining these "how to" strategies, we can better understand how businesses can leverage cutting-edge innovations to flourish in an increasingly competitive marketplace.

Innovative Technologies Shaping the Future of Machine Manufacturing

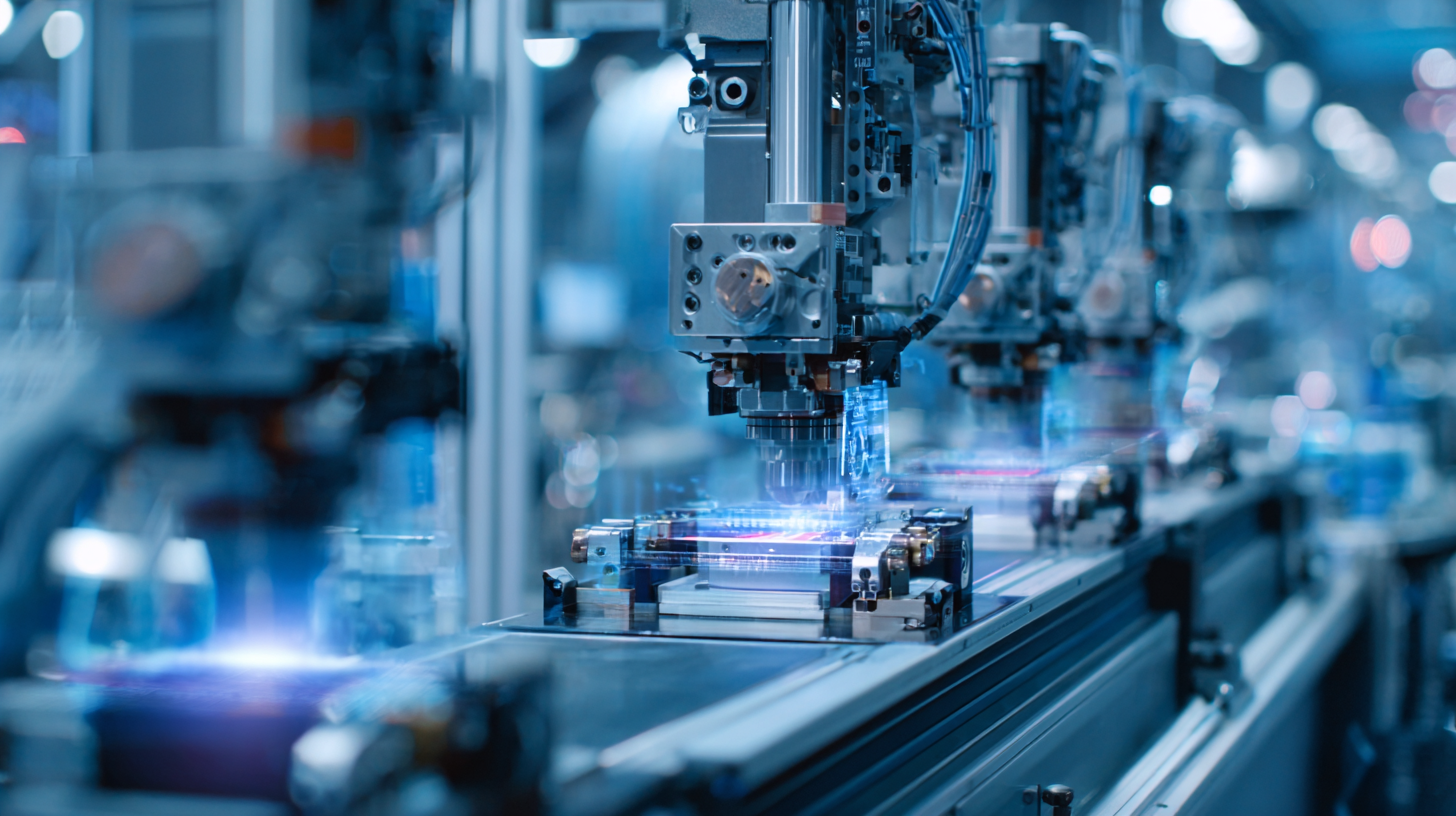

Innovative technologies are revolutionizing the landscape of machine manufacturing, paving the way for enhanced efficiency and precision. As industries increasingly adopt advanced computing, applied artificial intelligence, and automation, they are witnessing unprecedented improvements in production processes. For instance, AI is proving to be a game-changer by optimizing manufacturing workflows and enabling predictive maintenance, which leads to reduced downtime and increased productivity. The incorporation of smart machines allows for real-time data analysis, ensuring that manufacturers can swiftly respond to market demands and streamline operations.

Innovative technologies are revolutionizing the landscape of machine manufacturing, paving the way for enhanced efficiency and precision. As industries increasingly adopt advanced computing, applied artificial intelligence, and automation, they are witnessing unprecedented improvements in production processes. For instance, AI is proving to be a game-changer by optimizing manufacturing workflows and enabling predictive maintenance, which leads to reduced downtime and increased productivity. The incorporation of smart machines allows for real-time data analysis, ensuring that manufacturers can swiftly respond to market demands and streamline operations.

Moreover, the emergence of collaborative robots is transforming the workforce dynamics within manufacturing environments. These robots complement human tasks, creating a more agile and dynamic production line where humans and machines work in harmony. As technologies like digital twins and advanced robotics gain traction, industries can expect to see a significant shift in how machines are designed and utilized, leading to innovations that not only enhance operational efficiency but also drive sustainability. The future of machine manufacturing is characterized by the integration of these cutting-edge technologies, ultimately reshaping industries and redefining standards for productivity and innovation.

The Role of Automation in Enhancing Production Efficiency

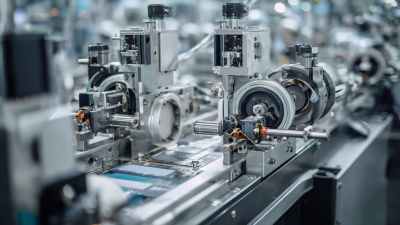

The manufacturing industry is undergoing a revolutionary transformation, primarily driven by advancements in automation technology. According to a report by McKinsey, companies that have implemented automation in their production processes have witnessed a productivity increase of up to 30%. This significant enhancement not only streamlines operations but also reduces human error, leading to higher quality outputs. As organizations adopt robotic process automation (RPA), streamlined production lines become the norm, enabling businesses to meet consumer demands more swiftly and efficiently.

In addition, the integration of Internet of Things (IoT) in manufacturing is a game-changer. Data from MarketsandMarkets indicates that the IoT in the manufacturing sector is expected to reach $346 billion by 2025, reflecting its pivotal role in enhancing production efficiency. Smart machines equipped with IoT capabilities enable real-time monitoring and predictive maintenance, reducing downtime and optimizing resource allocation. This blend of automation and smart technology not only elevates production capabilities but also positions companies competitively in a rapidly evolving marketplace.

Sustainable Practices in Machine Manufacturing: A Necessity for the Future

Sustainable practices are becoming essential in machine manufacturing as industries strive to reduce their environmental footprint while maintaining productivity and innovation. The integration of eco-friendly materials and energy-efficient processes is not just a trend; it is a necessity for the future. Manufacturers are increasingly investing in technologies that minimize waste, conserve resources, and lower carbon emissions. From utilizing recyclable materials in production to implementing renewable energy sources, these initiatives are transforming the landscape of machine manufacturing.

Moreover, adopting sustainable practices contributes to a company's long-term viability and competitiveness in the global market. As consumers become more environmentally conscious, their preferences shift towards products that are produced with a commitment to sustainability. This shift is prompting manufacturers to rethink their supply chains, focusing on ethical sourcing and transparent production methods. By embracing these innovations, industries can not only meet regulatory demands but also align with consumer values, paving the way for a more sustainable and responsible future in machine manufacturing.

The Future of Machine Manufacturing Innovations Transforming Industries - Sustainable Practices in Machine Manufacturing: A Necessity for the Future

| Innovation Type | Description | Sustainability Impact | Implementation Year |

|---|---|---|---|

| Additive Manufacturing | 3D printing technologies used to create complex parts layer by layer. | Reduces waste and energy consumption compared to traditional methods. | 2013 |

| IoT in Manufacturing | Integration of IoT devices for real-time monitoring and optimization. | Enhances efficiency and reduces downtime, leading to lower resource consumption. | 2016 |

| Biodegradable Materials | Using sustainable materials that break down naturally after use. | Minimizes environmental impact and enhances product lifecycle. | 2021 |

| Artificial Intelligence for Quality Control | AI systems analyzing production processes to detect defects. | Improves product quality and reduces scrap rates. | 2019 |

| Remote Monitoring and Maintenance | Using cloud technologies for remote equipment diagnostics and repairs. | Reduces travel emissions and enhances machine uptime. | 2020 |

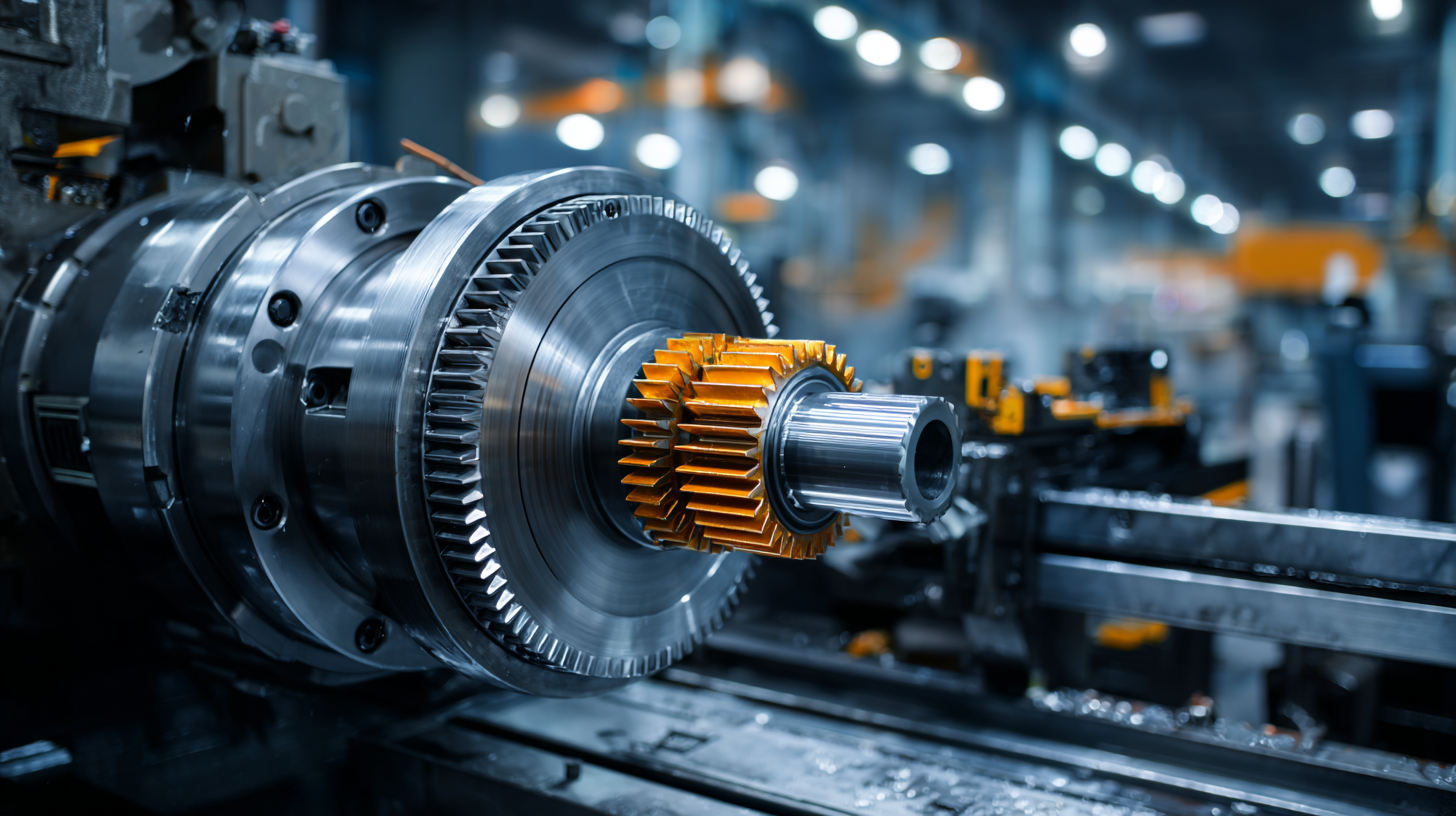

Advanced Materials and Their Impact on Manufacturing Processes

The focus on advanced materials is reshaping the landscape of manufacturing processes. Current research emphasizes the development of materials with unique properties that enhance energy efficiency and performance, playing a critical role in industries such as renewable energy and advanced electronics. For instance, innovations like laser-induced graphene are paving the way for flexible electronics, reflecting a shift towards materials that not only meet functionality but also support sustainability goals.

Moreover, emerging trends such as nanomaterials and advanced composites are set to revolutionize the semiconductor market from 2024 to 2034. These materials are not merely enhancing traditional manufacturing techniques but are integral to creating lightweight and durable products suitable for modern applications. The integration of artificial intelligence in these processes further accelerates advancements, allowing for better precision in material characterization and the development of smart, adaptive manufacturing systems. This synergy between technology and advanced materials is vital for driving the future of manufacturing industries.

The Integration of AI and IoT in Revolutionizing Industrial Operations

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is fundamentally reshaping industrial operations across various sectors. AI algorithms analyze vast amounts of data collected from IoT devices, allowing for predictive maintenance and enhanced decision-making processes. This synergy not only increases operational efficiency but also minimizes downtime, as machines can self-diagnose and communicate their status in real time. Consequently, companies can pivot towards more proactive strategies, optimizing productivity while reducing costs.

Moreover, IoT devices, equipped with sensors, gather insights on manufacturing performance, enabling continuous monitoring and refinement of processes. When combined with AI-driven analytics, industries gain a comprehensive understanding of their operational landscape, fostering innovation. For instance, smart factories now adapt to changes in demand instantly, ensuring that production aligns with market trends. This level of adaptability not only enhances competitiveness but also drives sustainable practices by minimizing waste and resource consumption, heralding a new era of manufacturing where technology and industry converge seamlessly.

Related Posts

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

Unlocking the Secrets of Manual Machines for Efficient Home Workspaces

-

Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.