Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

In the ever-evolving landscape of modern manufacturing, CNC machining stands out as a game-changing technology that has redefined precision and efficiency. As noted by industry expert Dr. Helen Thompson, a leading figure in CNC technology, "The precision offered by CNC machining not only enhances the quality of manufactured parts but also significantly reduces production time and costs." This capability to create complex geometries with unprecedented accuracy is transforming the way industries approach production.

CNC machining, or Computer Numerical Control machining, enables manufacturers to automate processes that were once labor-intensive and prone to human error. The result is a streamlined workflow that not only boosts productivity but also fosters innovation in design. As manufacturers strive to meet the demands of increasingly competitive markets, adopting CNC machining becomes not just an advantage but a necessity.

As we delve deeper into the revolutionary impact of CNC machining on modern manufacturing processes, it is essential to recognize how this technology is shaping the future. From aerospace to automotive, the implications are vast and far-reaching, heralding a new era of precision engineering that will likely set the standard for manufacturing excellence for years to come.

The Evolution of CNC Machining in Contemporary Manufacturing

CNC machining has dramatically transformed modern manufacturing processes, marking a significant evolution in how products are designed and produced. Originally focused on prototyping and small-scale production, CNC technology has expanded to serve a wide range of industries with increased efficiency and precision. This shift allows manufacturers to meet growing demands for customization and shorter lead times while minimizing waste.

As companies adopt new digital manufacturing technologies, they unlock unprecedented levels of productivity. Automation and advanced software are at the forefront of this change, enabling seamless integration between design and manufacturing. With the advent of full-service production capabilities, businesses can now take a product from conception through to final production, streamlining workflows and enhancing operational efficiency.

Tips: To maximize the benefits of CNC machining in your projects, invest in training for your team to ensure they are well-versed in the latest technologies. Additionally, consider utilizing simulation software to visualize the machining process before actual production, which can help in identifying potential issues early on. Lastly, regularly assess and update your machinery to stay competitive in an ever-evolving market.

Key Technologies Driving Precision in CNC Machining

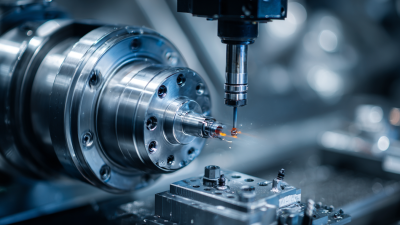

CNC machining has transformed modern manufacturing by integrating advanced technologies that enable unprecedented levels of precision and efficiency. Key technologies driving this revolution include computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. CAD allows engineers to create intricate designs with computer-generated accuracy, which are then translated into machine-readable formats by CAM software. This seamless transition from design to production minimizes the risk of human error and enhances the overall precision of manufactured components.

Moreover, the development of high-speed machining and multi-axis machining centers plays a critical role in improving precision in CNC processes. High-speed machining allows for faster tool movements and reduced cycle times, while multi-axis machines enable complex geometries and tighter tolerances to be achieved in a single setup. These advancements empower manufacturers to produce highly detailed parts with minimal setup time, streamlining workflows and increasing overall productivity. As a result, CNC machining continues to set new standards for precision in the manufacturing industry, driving innovation and competitiveness worldwide.

Efficiency Metrics: How CNC Enhances Production Processes

CNC machining has emerged as a cornerstone of modern manufacturing, significantly enhancing efficiency metrics across various production processes. According to a report by the International Federation of Robotics, CNC machines can increase productivity by up to 50% compared to traditional manufacturing methods. This is primarily due to their ability to operate continuously with minimal human intervention, reducing downtime and improving output consistency. Furthermore, the precision afforded by CNC technology allows for tighter tolerances in production, which minimizes waste and the need for rework—an essential factor in industries like aerospace, where components often require precision within microns.

In addition to improving productivity, CNC machining also facilitates a more flexible manufacturing environment. Research from MIT’s Center for Bits and Atoms indicates that CNC technology has the potential to adapt production lines in real-time, effectively responding to changes in demand without compromising efficiency. This agility not only shortens lead times but also enables manufacturers to adopt just-in-time production strategies, further optimizing resource utilization. As businesses increasingly embrace Industry 4.0 principles, integrating CNC machining into their workflows is vital for achieving substantial gains in efficiency, ultimately setting a new standard for the manufacturing landscape.

Customization and Flexibility: Meeting Market Demands through CNC

CNC machining has become a cornerstone of modern manufacturing, enabling companies to meet the ever-evolving demands of the market with unmatched customization and flexibility. Unlike traditional methods that often require lengthy adjustments and extensive manual labor, CNC (Computer Numerical Control) systems allow for rapid reconfiguration and precise modifications. This adaptability makes it possible for manufacturers to produce a wide range of products, from one-off prototypes to high-volume productions, all tailored to the specific needs of customers.

Moreover, the intricate programming capabilities of CNC machines facilitate the creation of complex designs that were previously difficult, if not impossible, to achieve. This technology empowers businesses to respond swiftly to trends and shifts in consumer preferences, allowing for shorter lead times and enhanced product offerings. As a result, companies can not only maintain relevance in a competitive marketplace but also push the boundaries of innovation, delivering bespoke solutions that cater to diverse client requirements. The integration of CNC machining thus represents a significant leap forward in the ability to customize and perfect manufacturing processes.

Unlocking Precision: How CNC Machining Revolutionizes Modern Manufacturing Processes

| Manufacturing Process | Customization Options | Flexibility Level | Production Speed (Units/Hour) | Typical Industry |

|---|---|---|---|---|

| CNC Milling | High precision; complex geometries | High | 15-50 | Aerospace |

| CNC Turning | Round shapes; various diameters | Medium | 20-60 | Automotive |

| CNC Laser Cutting | Intricate designs; materials of varying thickness | High | 30-100 | Electronics |

| CNC Waterjet Cutting | Versatile materials; no heat affected zones | Medium to High | 15-45 | Construction |

| CNC Plasma Cutting | Metal cutting; thick materials | Medium | 25-75 | Fabrication |

Future Trends: The Role of CNC in Smart Manufacturing Solutions

The role of CNC machining in the evolution of smart manufacturing is becoming increasingly pivotal. As modern industries demand higher precision and efficiency, the global CNC machine market is projected to grow significantly, reaching an estimated market size of approximately 450 billion yuan by 2025 in China alone. This growth is driven by the rising adoption of automation and the need for environmentally sustainable production practices. With advancements in technology, CNC machining offers solutions that not only enhance productivity but also enable manufacturers to transition from traditional methods to more automated processes.

Moreover, the CNC software market is also experiencing robust growth, with projections indicating a rise from $520 million in 2022 to around $880 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.2% from 2024 to 2030. This upsurge is indicative of the industry’s shift towards integrating smart manufacturing solutions, allowing for the seamless operation of complex machinery and improved operational efficiencies. As industries like automotive and precision engineering continue to evolve, the demand for high precision, efficiency, and innovative technologies will firmly establish CNC machining as a cornerstone of future manufacturing landscapes.

Unlocking Precision: The Role of CNC Machining in Modern Manufacturing

This chart illustrates the increasing adoption rate of CNC machining in modern manufacturing from 2020 to 2024, highlighting its pivotal role in enhancing precision and productivity in smart manufacturing solutions.

Related Posts

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

Revolutionizing Industries: The Impact of CNC Machining and Manufacturing on Modern Technology

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

Revolutionizing Manufacturing Processes with Advanced CNC Machining Equipment Solutions

-

Unlocking the Future of Manufacturing: The Role of Precision CNC Machining in Innovative Industries

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.