Exploring the Future: How Advanced Machining and Manufacturing Are Transforming Industries

The landscape of industries is undergoing a remarkable transformation driven by advancements in machining and manufacturing technologies. According to a report by Deloitte, the global advanced manufacturing market is projected to reach $6.4 trillion by 2025, underscoring the substantial economic impact of innovative machining techniques. As businesses embrace automation, additive manufacturing, and smart machining, the efficiency and precision of production processes are set to enhance, yielding significant cost savings and improved product quality. Furthermore, the World Economic Forum emphasizes that 70% of manufacturers are investing in digitization and smart technologies to remain competitive. This shift not only redefines operational capabilities but also ensures sustainability in production methods, aligning with evolving consumer demands. In essence, the synergy of advanced machining and manufacturing is poised to revolutionize industries, paving the way for unprecedented growth and innovation in the coming years.

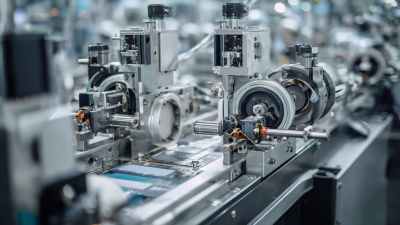

Understanding Advanced Machining Processes and Technologies

Advanced machining processes are redefining the landscape of manufacturing across various industries, driven by the need for precision, efficiency, and adaptability. Techniques such as computer numerical control (CNC), additive manufacturing, and advanced tooling are paving the way for innovations that were previously unimaginable. According to recent reports, industries utilizing advanced machining technologies have seen productivity increases of up to 30%, while also reducing material waste by over 20%. This transformation is essential for maintaining competitive advantage in fast-paced markets.

Tips: When considering the implementation of advanced machining processes, it's crucial to assess the compatibility with existing workflows and the potential return on investment. A pilot program can provide valuable insights without committing to large-scale changes. Furthermore, investing in training for your workforce will ensure they are equipped to leverage these sophisticated technologies effectively.

As advanced machining technologies evolve, the integration of data science and machine learning into manufacturing processes is becoming increasingly prevalent. By harnessing the power of data analytics, manufacturers can optimize operations, predict maintenance needs, and enhance product design. Reports indicate that companies that effectively integrate data science into their manufacturing strategies can expect a boost in operational efficiency by up to 50%. Embracing these advancements allows businesses not only to streamline their processes but also to innovate continually.

Integrating Automation and Robotics in Modern Manufacturing

The integration of automation and robotics is poised to reshape modern manufacturing dramatically. By 2024, the global food processing and handling equipment market is projected to reach a remarkable $117.81 billion, with a compound annual growth rate (CAGR) of 6.3% anticipated through to 2032. This growth is fueled by advancements in automation technologies that streamline production processes, reduce manual intervention, and enhance operational efficiency. Furthermore, in the automation laser tube cutting sector alone, the market is expected to surge from $865.53 million in 2024 to $1.82849 billion by 2032, underscoring the demand for precision and speed in manufacturing.

Simultaneously, the rise of Industry 4.0 underlines the significance of digital twins and artificial intelligence in manufacturing innovations. By utilizing enhanced simulation designs and high-resolution modeling, AI facilitates precise manufacturing processes that drive product innovation. The overall machinery manufacturing market, currently valued at $745.73 billion in 2024, is forecasted to grow at a CAGR of 7.5%, highlighting how interconnected technologies such as IoT, 5G, and big data are increasingly vital to the industry's evolution. This interconnectedness not only improves factory automation but also enhances data-driven decision-making, ensuring manufacturers stay competitive in a fast-evolving market landscape.

Adopting Sustainable Practices in Advanced Manufacturing

As industries evolve, the importance of adopting sustainable practices in advanced manufacturing becomes increasingly paramount. Modern techniques such as additive manufacturing, robotics, and smart automation not only enhance efficiency but also minimize waste and energy consumption. By integrating sustainable materials and processes, manufacturers can significantly reduce their environmental footprint while maintaining high-quality production standards. This shift not only benefits the planet but also addresses the growing consumer demand for environmentally responsible products.

Tips for implementing sustainable practices include conducting a lifecycle analysis of materials to choose greener alternatives, utilizing energy-efficient machinery, and optimizing production processes to reduce waste. Collaborating with suppliers who prioritize sustainability can further enhance the overall ecological impact of your operations. Continuous training and education of employees about sustainable practices will also foster a culture of responsibility and innovation within the workforce.

Emphasizing sustainability is not just about compliance but is rapidly becoming a competitive advantage. Industries that prioritize eco-friendly innovations will likely lead the way in the market, attracting consumers who are more conscious of their choices. By focusing on sustainable practices in advanced manufacturing, companies can position themselves favorably for future growth while contributing to a healthier planet.

Leveraging Data Analytics for Enhanced Production Efficiency

The rapidly evolving landscape of advanced machining and manufacturing is significantly influenced by the integration of data analytics. According to a report by McKinsey, companies that leverage data analytics in their operations can achieve up to a 50% increase in production efficiency. This transformative capability allows manufacturers to optimize processes, reduce downtime, and fine-tune resource allocation, ultimately leading to enhanced productivity.

One notable example is the adoption of predictive maintenance, where machine learning algorithms analyze equipment performance data to foresee potential failures. A study by Deloitte found that predictive analytics can reduce maintenance costs by up to 30% and significantly minimize unplanned downtime. As industries increasingly rely on data-driven decisions, the potential for real-time adjustments and enhancements becomes a game-changer, driving the manufacturing sector into an era of unprecedented efficiency and agility.

By continuously harnessing insights from data, manufacturers are not only improving operational efficiency but also redefining their competitive strategies. The emphasis on leveraging data analytics not only ensures sustainable growth but also positions companies to respond swiftly to market changes, meeting customer demands with agility and precision.

Exploring Future Trends in Smart Manufacturing Innovations

Smart manufacturing innovations are at the forefront of transforming industries, paving the way for more efficient production processes. Techniques such as automation, data analytics, and the integration of IoT technologies are enabling manufacturers to optimize operations, reduce waste, and improve quality. The use of artificial intelligence in predictive maintenance ensures that machines operate smoothly, minimizing downtime and increasing productivity. As industries adopt these technologies, the competitive landscape is rapidly evolving, leaving those who resist change at a disadvantage.

Tips: To stay ahead in this shifting landscape, consider investing in training programs for your workforce to familiarize them with the latest technologies. Collaboration between departments can also drive innovation—encourage cross-functional teams to brainstorm solutions that leverage these advanced tools. Finally, keep an eye on emerging trends in materials and processes; remaining adaptable will be key to navigating the complexities of smart manufacturing. Embracing a culture of continuous improvement will not only enhance efficiency but also position your organization as a leader in your industry.

Related Posts

-

Unlocking the Secrets of CNC Machining Precision for Optimal Performance

-

5 Ways CNC Machining and Manufacturing Transforms Your Production Process

-

The Future of Machine Tools Innovations Transforming Manufacturing Processes

-

Unlocking Precision: How Manual Machines Boost Productivity with 30% Efficiency Gains in Manufacturing

-

Revolutionizing Manufacturing Efficiency with Advanced CNC Machine Tools and Smart Technologies

-

The Future of Precision Machining Innovations Transforming Industry Standards

We Meet Our Clients Needs.

Meeting the diverse needs of our clients, we have complete machining facilities for everything from single part prototypes to large quantity production. Our small size is one of our biggest assets. It allows us to control costs and maintain the highest of standards.

Quality orientated and delivery always on time or earlier than originally promised.

Strongly recommend MSD.